Shipping Order

- Overview

- Add Order

- Edit Order

- Cancel Order

- Close Order

- Add Line

- Add Detail

- Allocate

- Ship

- Packaging

- Unship

- Cross-Docking

- History

- Print Labels

- Shipping Order Reports

Required Permissions

- View Shipping Orders

- ability to search and view Shipping Orders

- Modify Shipping Orders

- ability to add, view, edit, cancel and close Shipping Orders

- Allocate Shipping Orders

- ability to allocate stocks for Shipping Orders

- ability to unallocate previously allocated stocks for Shipping Orders

- Ship

- ability to add, edit details to order lines in Shipping Orders

- ability to ship stocks in Shipping Orders

- ability to apply Assign To All function in Shipping Orders

- Unship

- ability to unship previously shipped stocks in Shipping Orders

- View Reports

- ability to print and export Shipping Order Reports

- View Cost

- ability to view Total Cost in Shipping Orders

- ability to view Unit Cost of details in Shipping Orders

- Modify Cost

- ability to view Total Cost in Shipping Orders

- ability to view and edit Unit Cost of details in Shipping Orders

- View Price

- ability to view Amount in Shipping Orders

- ability to view Unit Price of lines in Shipping Orders

- Modify Price

- ability to view Amount in Shipping Orders

- ability to view and edit Unit Price of lines in Shipping Orders

Overview

Shipping is a process of shipping stocks from the source site to customers. That means the physical movement of stocks from the warehouse. Once the stock is shipped, it is removed from Inventory.

CoreIMS supports the shipping process only through Shipping Orders.

Add Order

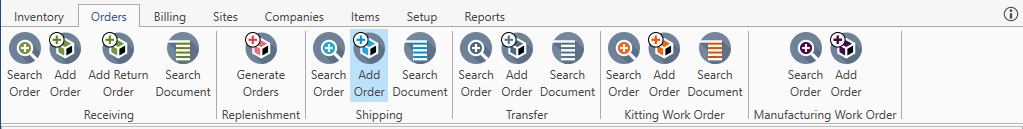

- Go to Orders tab of the main menu.

- Select Shipping -> Add Order menu item.

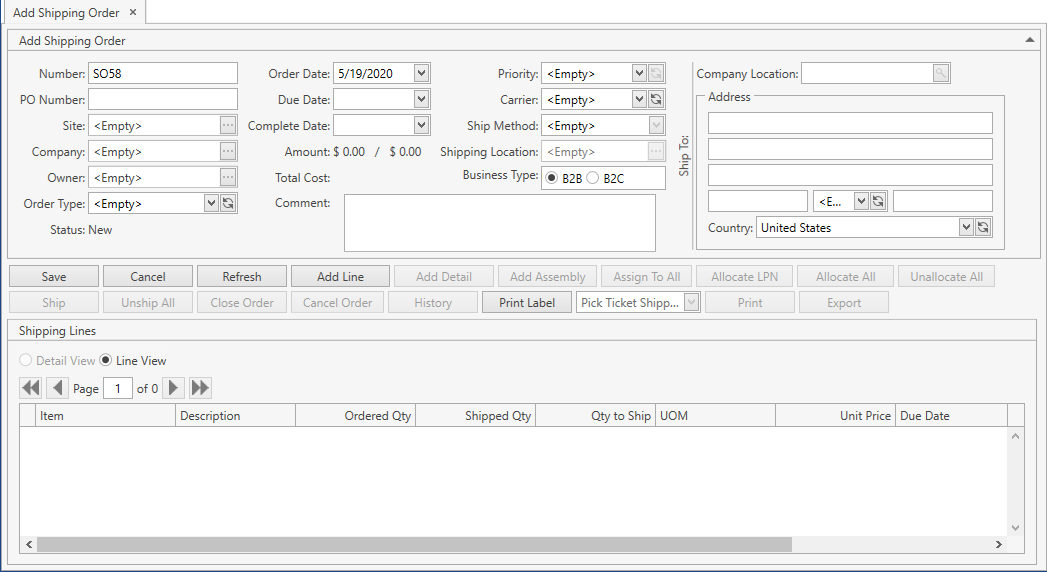

The following window will show up:

- Specify all the necessary attributes:

| Attribute | Required/Optional | Comment |

|---|---|---|

| Number | Required | Shall be unique across the system; automatically prepopulated by the system if Autonumbering Setting for Shipping Order is turned on. |

| PO Number | Optional | |

| Site | Required | Drop-down list of active Sites that you have access to. The necessary Site can be searched by the ellipsis button [...] as well. CoreIMS automatically prepopulates the field, if you have a specified Default Site (please refer to Users section). |

| Company | Required* | *If Business Type is specified as B2B (Business-to-Business). Drop-down list of active Customer Companies. The necessary Company can be searched by the ellipsis button [...] as well. |

| Owner | Optional | Drop-down list of active Companies marked as Owner. The necessary Company can be searched by the ellipsis button [...] as well. Visible only if Ownership mode is set up as Item Level or Stock Level in System Settings. If you (your CoreIMS user) have a specified Owner (please refer to Users section), you will be able to specify only this Owner or leave the Shipping Order without an owner. |

| Order Type | Optional | Drop-down list of Order Types. |

| Status | Required | Non-editable; CoreIMS auto populates the field with one of the following values: New, In Process, Closed, Canceled. |

| Order Date | Required | CoreIMS prepopulates the field with the current date. You can change it, if necessary. |

| Due Date | Optional | |

| Complete Date | Optional | Non-editable; CoreIMS auto populates the field with the current date when the Shipping Order gets into Closed status. |

| Amount: Total Ordered Price/Total Shipped Price | Required | Non-editable; CoreIMS auto populates the field according to the following: Total Ordered Price = SUM (Unit Price * Ordered Qty) of order lines Total Shipped Price = SUM (Unit Price * Shipped Qty) of order lines |

| Total Cost | Required | Non-editable; CoreIMS auto populates the field according to the following: Total Cost = SUM (Unit Cost * Quantity) of order details |

| Comment | Optional | |

| Priority | Optional | Drop-down list of the predefined system values: Rush, Low, Medium, High. |

| Carrier | Optional | Drop-down list of the values defined in Configuration section. |

| Ship Method | Optional | Drop-down list of the values defined in Configuration section. You can specify the ship method for the selected carrier. |

| Shipping Location | Optional | Drop-down list of active Locations on the selected Site. The necessary Location can be searched by the ellipsis button [...] as well. CoreIMS auto populates the field if Site has a specified Default Shipping Location (please refer to Sites section). This Location is used while picking from the mobile app. |

| Business Type | Required | B2B (Business-to-Business) or B2C (Business-to-Consumer). |

| Ship To: Company Location/Name | Optional* | *If Business Type is specified as B2B (Business-to-Business). For B2C (Business-to-Consumer) the field is required. CoreIMS prepopulates Company Location if Company has only one active address (please refer to Companies section). |

| Ship To: Address | Optional | In case Company Location is not prepopulated, CoreIMS automatically prepopulates Country if Default country is specified in System Settings. For United States you can specify the state. For other countries city and postal code are accepted. |

| Custom Fields | Optional | If Shipping Order has any Active Custom Fields. |

Click Save button. The order will be saved in CoreIMS. Now you can edit the order.

Click Cancel button if you want to cancel adding of a new Shipping Order.

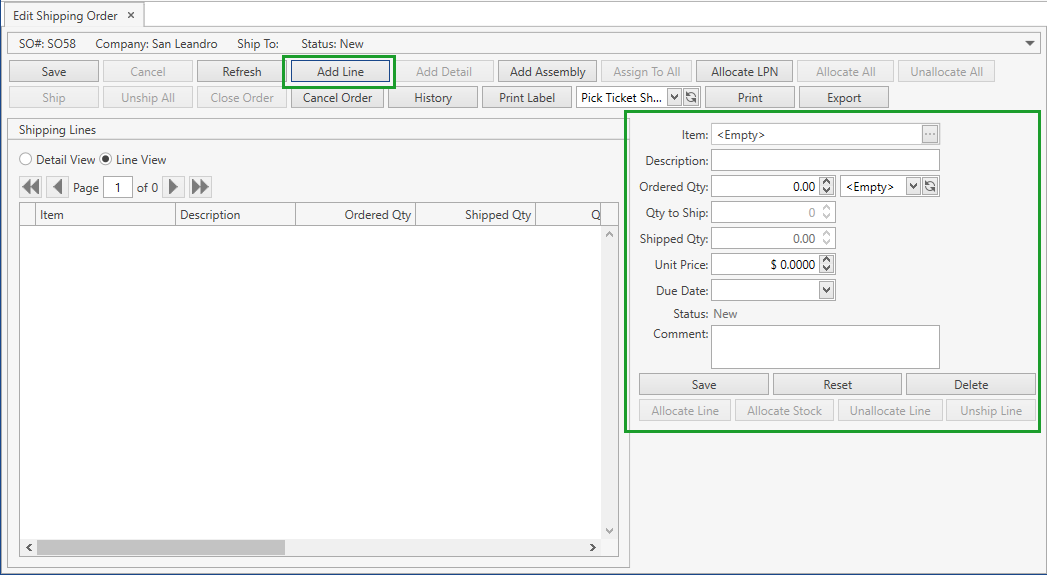

You can also save a new Shipping Order by clicking Add Line button:

- a new order will be saved;

- the order header will be collapsed (please refer also to Orders: View Features section);

- the pop-up/window for adding a new line will show up:

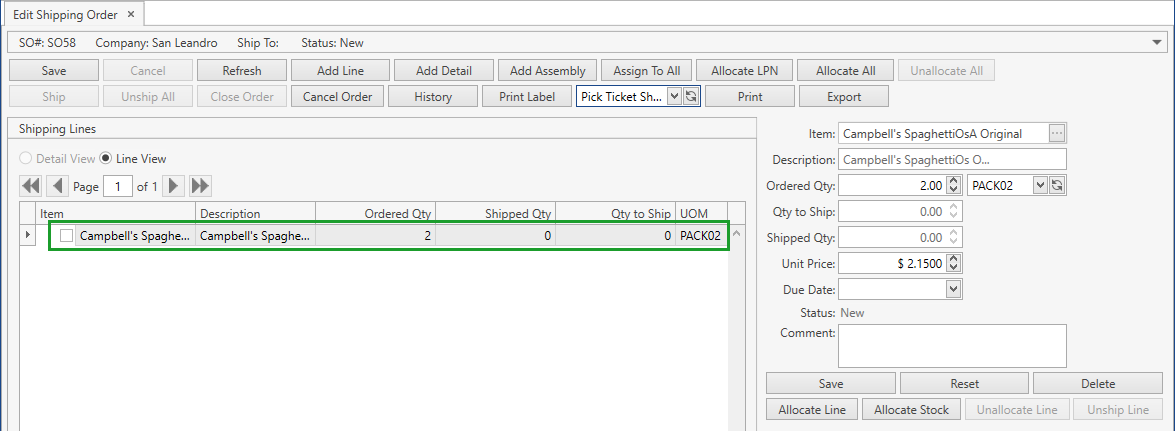

Edit Order

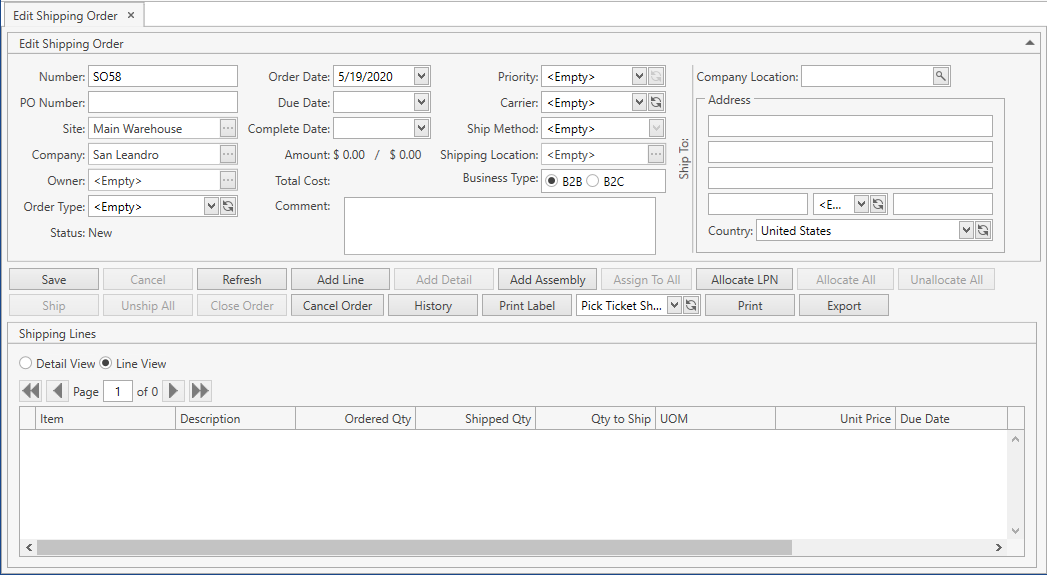

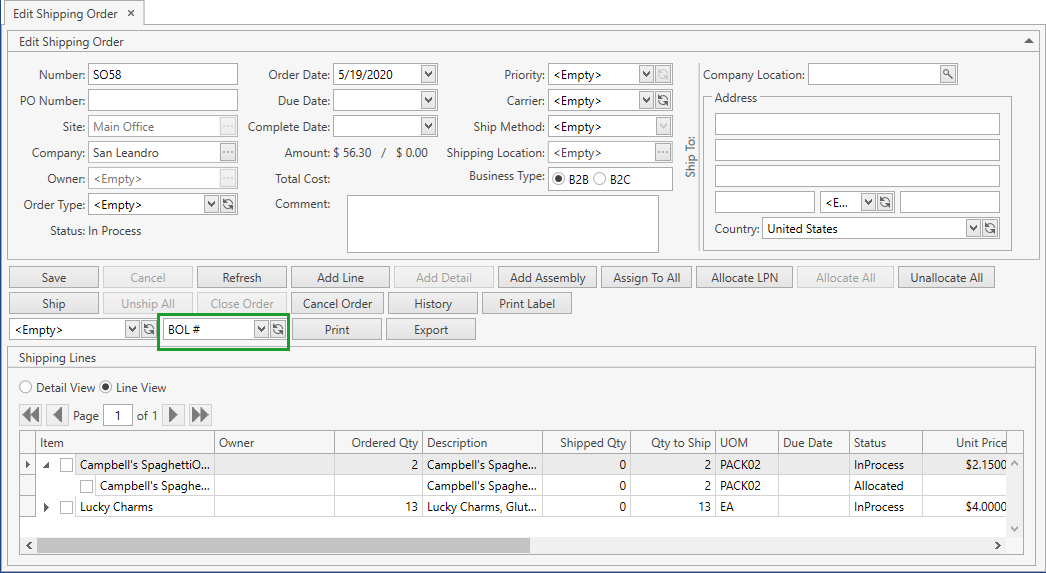

After saving the changes in Add Shipping Order tab, you will be redirected to Edit Shipping Order tab:

You can also get to Edit Shipping Order tab from Search Shipping Order screen.

Please refer also to Orders: View Features section for the details on different view parameters.

You can do the following:

Edit all the necessary order attributes.

Click Save button to apply the changes made within the order header.

Click Cancel button to reset the unsaved changes within the order header.

Click Refresh button to reset the unsaved changes within the order header and update the displayed Shipping Order with the up-to-date data from the database.

Click Add Line button to add a line to the order.

Click Add Detail button to add a detail to the selected order line.

Click Add Assembly button to add a line with an assembly or its components to the order.

Click Assign To All button:

- to assign the same attributes within one transaction to all order details in New status

- to create new details for the order lines that have not been closed (i.e. fully shipped)

Click Allocate LPN button to manually select LPN and allocate stocks from it.

Click Allocate All/Unallocate All button to allocate/unallocate stocks for order lines.

Click Ship button to perform the shipping operation.

Click Unship All button to unship previously shipped stocks.

Click Close Order button to manually close the order when it was partially shipped.

Click Cancel Order button to cancel the order in case there are no stocks shipped within the current order.

Click History button to view a list of Shipping Documents for the current order.

Click Print Label button to print a label for the order line(s)/detail.

Click Print/Export button to print/export the selected report for the current order.

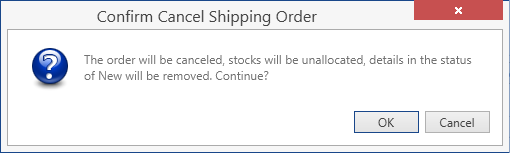

Cancel Order

- Click Cancel Order button.

- Confirm the operation:

Once you confirm the operation, CoreIMS will do the following:

- reset Ordered Qty for all order lines to 0;

- unallocate stocks;

- delete the details in New status;

- assign to the order lines Closed status;

- assign to the order Canceled status.

Even if the order was canceled, it is still available in CoreIMS and you can search, view and edit it.

Troubleshooting

- Cancel Order button is disabled.

Check statuses of the order details. Cancel Order button is enabled only if there are no details in Shipped status in the order.

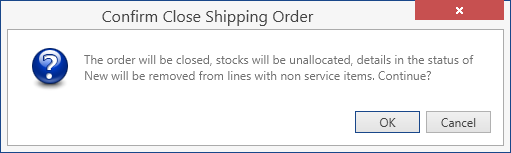

Close Order

- Click Close Order button.

- Confirm the operation:

Once you confirm the operation, CoreIMS will do the following:

For the order:

- update Amount in the order header;

- assign to the order lines Closed status;

- assign to the order Closed status.

For the lines of non-service items:

- unallocate stocks;

- delete the details in New status;

- update Ordered Qty: Ordered Qty will be equal to Shipped Qty.

For the lines of service items:

- create the respective detail in New status with Quantity = Ordered Qty - (Shipped Qty + Qty to Ship) if Quantity value is greater than 0;

- ship all the details in New status and assign to them Shipped status;

- add the respective record to the last generated BOL (Bill of Lading) of the order.

Troubleshooting

- Close Order button is disabled.

Check statuses of the order details. Close Order button is enabled only if there is at least one detail in Shipped status in the order.

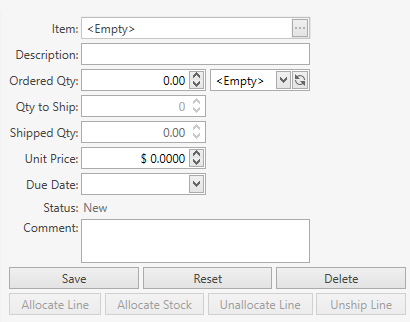

Add Line

- Open the necessary order.

- Click Add Line button. The following window will show up:

- Specify the line attibutes according to the following:

| Attribute | Required/Optional | Comment |

|---|---|---|

| Item | Required | Drop-down list of active items. The necessary item can be searched by the ellipsis button [...] as well. If Ownership mode is set up as Item Level: if you (your CoreIMS user) have a specified Owner (please refer to Users section) and/or you indicated Owner in the order header, you will be able to select an item only of this Owner or without an owner. |

| Description | Optional | Non-editable; CoreIMS auto populates the field if the respective item has the specified description. |

| Ordered Qty: Qty + UOM | Required | You cannot enter the decimal quantity for serial-controlled items. CoreIMS auto populates UOM with Default Sales UOM if it specified for the respective item. Otherwise, CoreIMS auto populates UOM with the base UOM of Quantity UOM Class specified for the respective item. |

| Qty to Ship | Required | Non-editable; CoreIMS auto populates the field according to quantities and statuses of the line's details. |

| Shipped Qty | Required | Non-editable; CoreIMS auto populates the field according to quantities and statuses of the line's details. |

| Unit Price | Optional | CoreIMS auto populates the field if Unit Price is specified for the respective UOM in Item UOMs tab. |

| Due Date | Optional | |

| Status | Required | Non-editable; CoreIMS auto populates the field with one of the following values: New, In Process, Closed. |

| Comment | Optional |

- Click Save button. A new line in New status will be added to the order:

Click Reset button if you want to cancel adding of a new order line.

You can delete an order line if it doesn't have any details by clicking Delete button.

Add Assembly

You can also add an order line(s) by clicking Add Assembly button. This is a common functionality for orders. Please refer to this section for details.

Add Detail

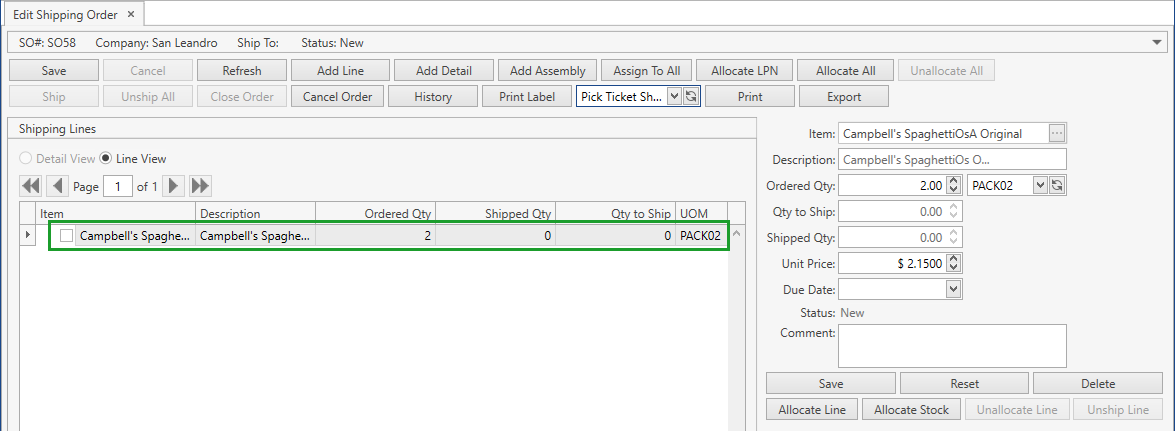

- Select the line you want to add a detail to.

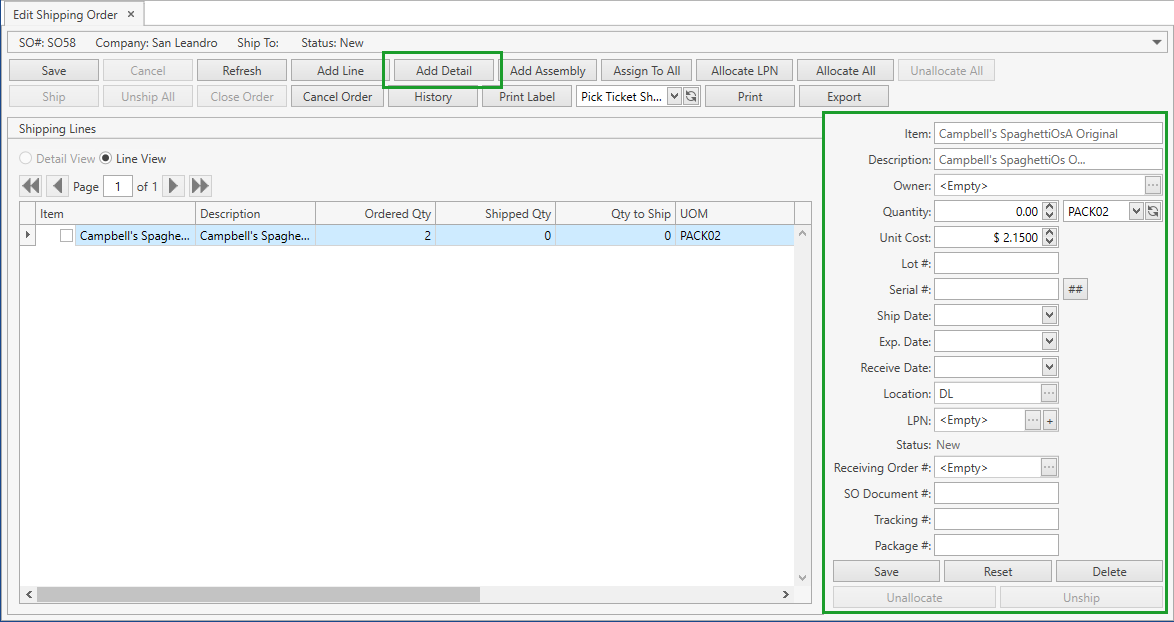

- Click Add Detail button. The following window will show up:

- Specify the detail attibutes according to the following:

| Attribute | Required/Optional | Comment |

|---|---|---|

| Item | Required | Non-editable; CoreIMS auto populates the field with the respective item from the order line. |

| Description | Optional | Non-editable; CoreIMS auto populates the field if the respective item has a description. |

| Owner | Optional | If Ownership mode is set up as No: non-visible. If Ownership mode is set up as Item Level: non-editable; CoreIMS auto populates the field with Owner of the respective item from the order line. If Ownership mode is set up as Stock Level: a drop-down list of active Companies marked as Owner. The necessary Company can be searched by the ellipsis button [...] as well. If you (your CoreIMS user) have a specified Owner (please refer to Users section) and/or you indicated Owner in the order header, you will be able to specify only this Owner or leave the detail without an owner. |

| Quantity | Required | For non-serial controlled items: CoreIMS prepopulates UOM field with the respective UOM from the order line. For serial-controlled items: CoreIMS prepopulates UOM field with the base UOM of Quantity UOM Class specified for the respective item. Qty is 1 by default and non-editable for you; CoreIMS automatically populates this field according to the quantity of serial numbers. |

| Unit Cost | Optional | CoreIMS prepopulates the field if Unit Cost is specified for the respective UOM in Item UOMs tab. |

| Lot # | Required* | *If the item is lot-controlled. |

| Serial # | Required* | *If the item is serial-controlled. If Autonumbering Setting for Serial Number is turned on, you can generate Serial # for non-serial controlled items by clicking on  button near Serial # field. Please refer to this section to view how to assign serial numbers for serial-controlled items. button near Serial # field. Please refer to this section to view how to assign serial numbers for serial-controlled items. |

| Ship Date | Optional | Non-editable; CoreIMS auto populates the field once the detail was shipped. |

| Exp. Date | Required* | *If FEFO picking sequence is supported for the respective item. |

| Receive Date | Required* | *If FIFO or LIFO picking sequence is supported for the respective item. |

| Location | Required | CoreIMS prepopulates the field with Default Location specified for the Site from the order header. |

| LPN | Optional | Drop-down list of LPNs located on the Site from the order header. The necessary LPN can be searched by the ellipsis button [...] as well. You can also add a new LPN. |

| Status | Required | Non-editable; CoreIMS auto populates the field with one of the following values: New, Allocated, Shipped. |

| Receiving Order # | Optional | CoreIMS auto populates the field during the cross-docking procedure. |

| SO Document # | Optional | Non-editable; CoreIMS auto populates the field once the detail was shipped with the respective number of BOL (Bill of Lading). |

| Tracking # | Optional | Non-editable; CoreIMS auto populates the field during the integration with the external carrier system (UPS) if Track Package is turned on in System Settings. |

| Package # | Optional | Non-editable; CoreIMS auto populates the field during the integration with the external carrier system (UPS) if Track Package is turned on in System Settings. |

| Custom Fields | Optional | If Stock has any Active Custom Fields. |

- Click Save button. A detail in New status will be added to the order line:

Click Reset button if you want to cancel adding of a new order detail.

You can delete an order detail if it hasn't been shipped yet by clicking Delete button.

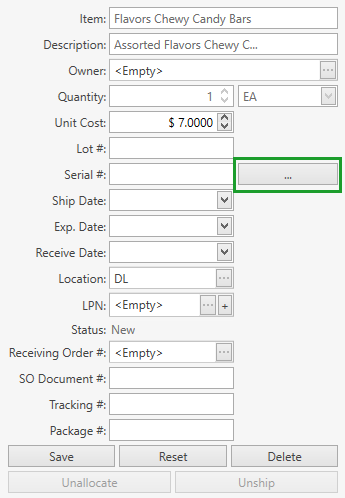

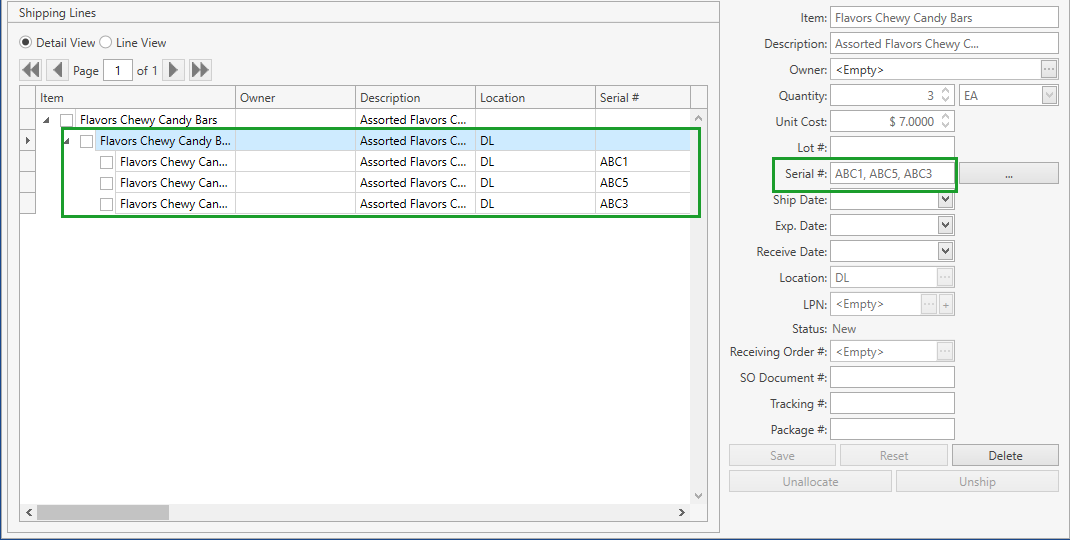

Add Detail for Serial-Controlled Items

- Select the line of the serial-controlled item you want to add a detail to.

- Click Add Detail button.

- Specify the detail attibutes according to the section above.

- Enter manually serial numbers separated by comma or click on

near Serial # field to assign seial numbers automatically (please refer to this section for details):

near Serial # field to assign seial numbers automatically (please refer to this section for details):

Once you saved the detail, CoreIMS automatically adds as many details as serial numbers you specified:

Assign To All

You can update the detail attributes and even add details in New status for all order lines within one transaction by clicking Assign To All button. This is a common functionality for orders. Please refer to this section for details.

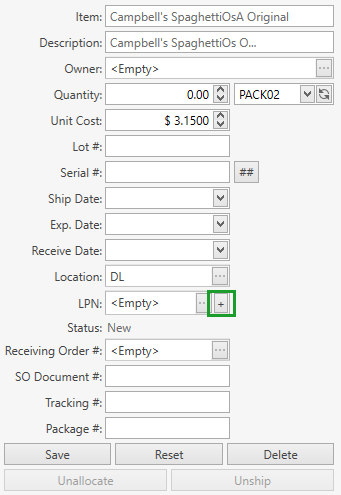

Add LPN

You can add a new LPN to the detail in New status that has not been shipped yet by clicking '+' button next to LPN field:

This is a common functionality for orders. Please refer to this section for details.

Allocate

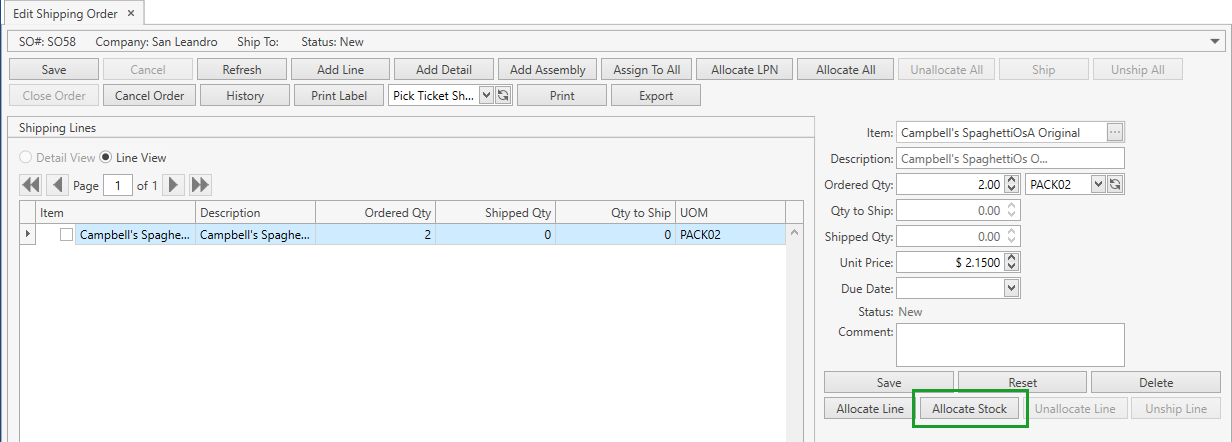

Allocate Stock

- Select the line you want to manually allocate.

- Click Allocate Stock button:

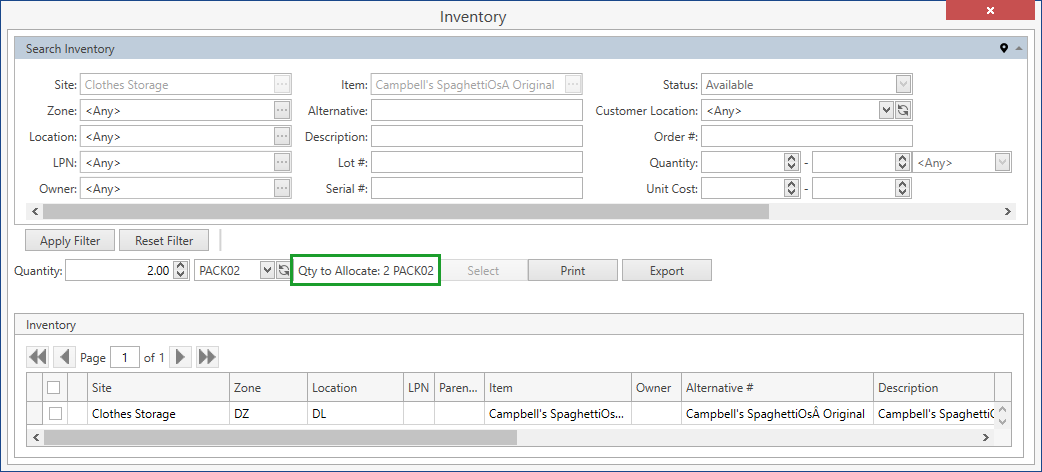

Inventory window will show up:

CoreIMS calculates Qty to Allocate as the quantity remaining to be allocated:

Qty to Allocate = Ordered Qty - (Shipped Qty + Qty to Ship)

For further details please refer to Allocate Stock section.

Allocate Line / Allocate All

- Select the line you want to be automatically allocated by CoreIMS.

- Click Allocate Line button:

- Alternatively, you can simply click Allocate All button. Then CoreIMS automatically allocates all the order lines.

CoreIMS will try to allocate an order line if the line's remaining quantity is greater than 0. The remaining quantity is calculated as follows:

Remaining Qty = Ordered Qty - (Shipped Qty + Qty to Ship)

Please refer to this section to learn more about the algorithm which CoreIMS uses for the allocation. It's possible that an order line would be allocated only partially or ended up being not allocated at all due to the lack of the inventory.

Allocate LPN

You can allocate an LPN (without even adding preliminary respective order lines) by clicking Allcate LPN button. This is a common functionality for orders. Please refer to Allocate LPN section for details.

Unallocate

- Select the line you want to unallocate.

- Click Unllocate Line button:

Alternatively, you can simply click Ullocate All button. Then CoreIMS automatically unallocates all previously allocated order lines.

If you want to unallocate the specific detail, select this detail and then click Unallocate button:

Ship

- Create order lines.

- Allocate stocks or add details manually to these lines.

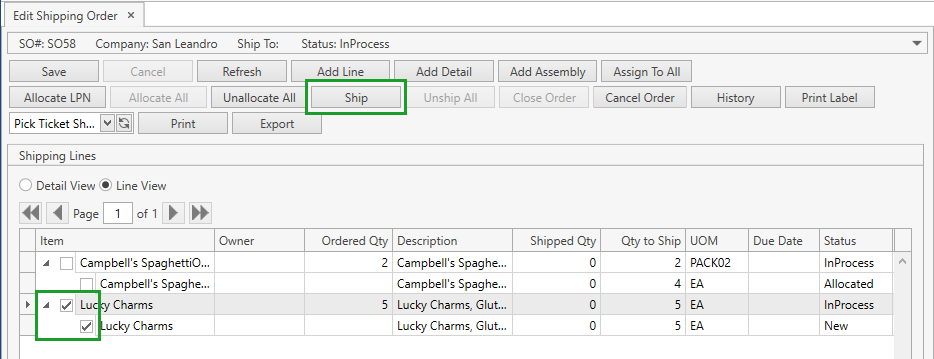

- If you don't want some of the lines/details to be shipped, you can check only those lines/details that are to be shipped as shown below:

If you didn't check any of the order lines/details, CoreIMS will try to ship all of the details that are in New or Allocated status.

- Click Ship button. The following window will show up:

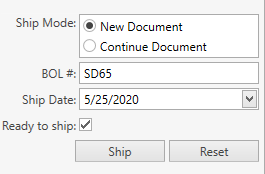

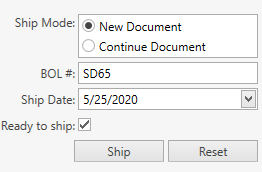

Select Ship Mode:

- New Document: CoreIMS will generate a new Shipping Document (BOL, i.e Bill of Lading); you need to specify BOL # – CoreIMS prepopulates BOL # if Autonumbering Setting for Shipping Document is turned on.

- Continue Document: CoreIMS will record the result of the shipping operation into one of the Shipping Documents generated during the previous shipping operations within the current Shipping Order.

Change Ship Date, if needed. By default the date is set to the current date.

Ready to ship flag is visible only if Track Package is enabled in System Settings. Whether this flag is checked or not by default depends on the status defined in System Settings in Shipping Package attribute. Please refer also to Packaging section for more details.

Click Reset button to cancel the operation.

Click Ship button to confirm the operation. CoreIMS does the following:

- for details in Allocated status: ships them and gets into Shipped status;

- for details in New status: tries to match these details with stocks on the inventory (if one or more optional attributes are not assigned to the manually created detail, CoreIMS will find stocks where these attributes have any value; if a detail has a specified Serial #, CoreIMS will only search for matches by Serial # – all other attributes will be ignored):

- if the necessary stock(s) is found, CoreIMS ships this stock(s) and gets the New detail into Shipped status -> the detail is fully shipped;

- if the necessary stock(s) is not found:

- if Allow Negative Stocks flag is checked in System Settings, CoreIMS creates the stock in Available status with the necessary negative quantity on the inventory and gets the New detail into Shipped status -> the detail is fully shipped;

- if Allow Negative Stocks flag is unchecked in System Settings, CoreIMS doesn't ship the New detail and leaves it as is -> the detail is not shipped;

- if the necessary stock(s) is found, but its quantity is less than you need to ship:

- if Allow Negative Stocks flag is checked in System Settings, CoreIMS creates the stock in Available status with the lacking negative quantity and gets the New detail into Shipped status -> the detail is fully shipped;

- if Allow Negative Stocks flag is unchecked in System Settings, CoreIMS ships the stock(s) found on the inventory and splits the New detail into two: the first one with the quantity of the found stock and Shipped status, the second one – with the rest of the quantity and New status -> the detail is partially shipped.

Packaging

Overview

A package is an object or set of objects, wrapped, boxed or tied in a bundle for transportation or mailing.

Packages are created in CoreIMS and then imported to the external carrier system (UPS), where they are processed and get Tracking # and Shipping Charge assigned. Tracking # and Shipping Charge are exported then back to CoreIMS.

You need to have Track Package option enabled to create and process packages (see System Settings).

You can start creating packages via Ship process:

Ready to ship flag is visible only if Track Package is enabled in System Settings. Whether this flag is checked or not by default depends on the status defined in System Settings in Shipping Package attribute:

Ready to ship is checked: the package will obtain Ready For Shipment status.

Ready to ship is unchecked: New status will be assigned to the package.

After Ship button is clicked, a package will be automatically created.

The package will obtain the same number as BOL # with the addition of the index number. For example, SD11-1, SD11-2 for an order with two packages for BOL # SD11. You can see the list of packages if you click History in the order header (refer also to History section for more details). The following window will open:

Package statuses:

New: a newly created package with Ready to ship option unchecked;

Ready For Shipment: a newly created package with Ready to ship option checked;

Shipped: the package has been processed in the external carrier system (i.e. it has a Tracking #);

Void: the package was voided in the external carrier system.

Import to the Carrier System

If the packages have Ready For Shipment status, they can be imported to the external carrier system for further processing. The packages can be exported back to CoreIMS when the process has finished. You can switch New package status to Ready For Shipment manually by selecting a new package and clicking Ready to Ship button (refer to this section as well).

Export from the Carrier System

As the result of the export process, the carrier system returns to CoreIMS the shipping info about packages (Tracking # and Shipping Charge). CoreIMS processes this information according to the following:

- CoreIMS writes Tracking # to the Shipping Order details which have the same Shipment and Package numbers.

- Each Shipping Charge is added to Shipping Order as a line of service item (configured in System Settings) as follows:

- Ordered Qty = Shipped Qty = 1;

- Line UOM = Detail UOM = Base UOM of Item Quantity UOM Class;

- Location = Default Location of Site;

- Unit Price = a value of the actual Shipping Charge from the carrier system;

- Detail has Shipped status and is added to the Shipment Document the package was created from.

- CoreIMS updates Amount on the Shipping Order header.

Unship

You can unship a detail, a line or the whole order.

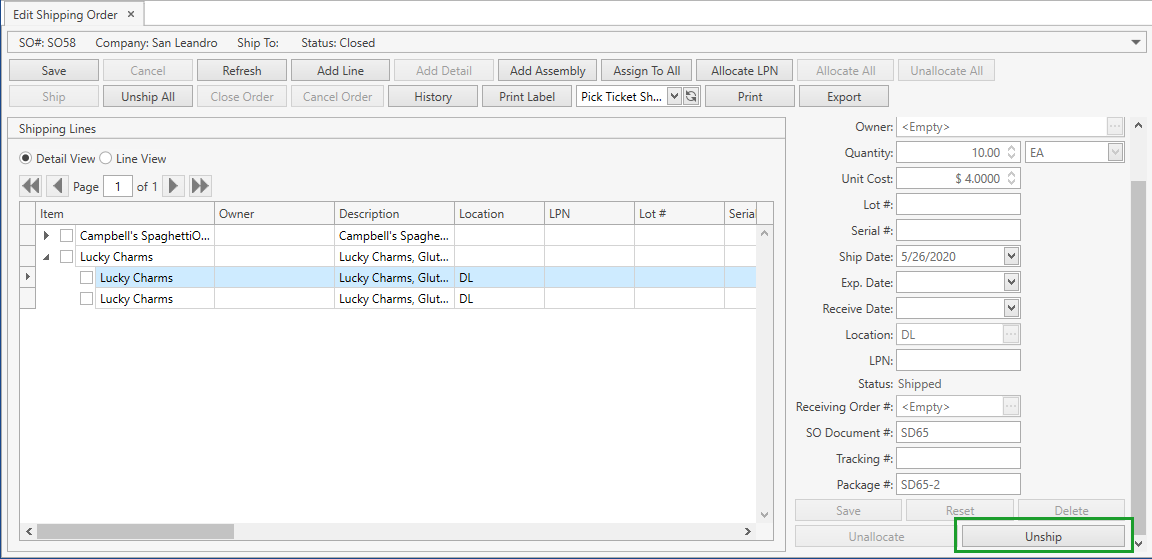

To unship a detail:

- Select the detail you want to unship.

- Click Unship button:

The following dialogue window will open (for non-service items):

- Specify the quantity to unship and Stock Unship Mode: Restock or Reallocate (the option that is checked by default is defined in System Settings).

If Unship Qty <> Shipped Qty, CoreIMS will do the following:

If you selected Restock Unship Mode:

- log Transaction History;

- create a stock according to the detail attributes with Qty = Unship Qty from Unship stock pop-up;

- update Shipped Qty for the line whose detail has been unshipped, where ‘New’ Shipped Qty = Shipped Qty - Unshipped Qty.

If you selected Reallocate Unship Mode:

- log Transaction History;

- create a stock according to the detail attributes with Qty = Unship Qty from Unship stock pop-up;

- update Shipped Qty for the line whose detail has been unshipped, where ‘New’ Shipped Qty = Shipped Qty - Unshipped Qty;

- allocate just created stock to the line whose detail you unshipped.

If Unship Qty = Shipped Qty, CoreIMS will do the following:

If you selected Restock Unship Mode:

- log Transaction History;

- create a stock according to the detail attributes;

- delete the detail that has been unshipped.

If you selected Reallocate Unship Mode:

- log Transaction History;

- create a stock according to the detail attributes;

- delete the detail that has been unshipped;

- allocate just created stock to the line whose detail you unshipped.

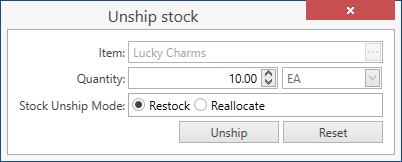

To unship a line:

- Select the line you want to unship.

- Click Unship Line button:

You will get the following result:

- The line gets New status.

- Shipped Qty of the line is equal to ‘0’.

- Line details are deleted.

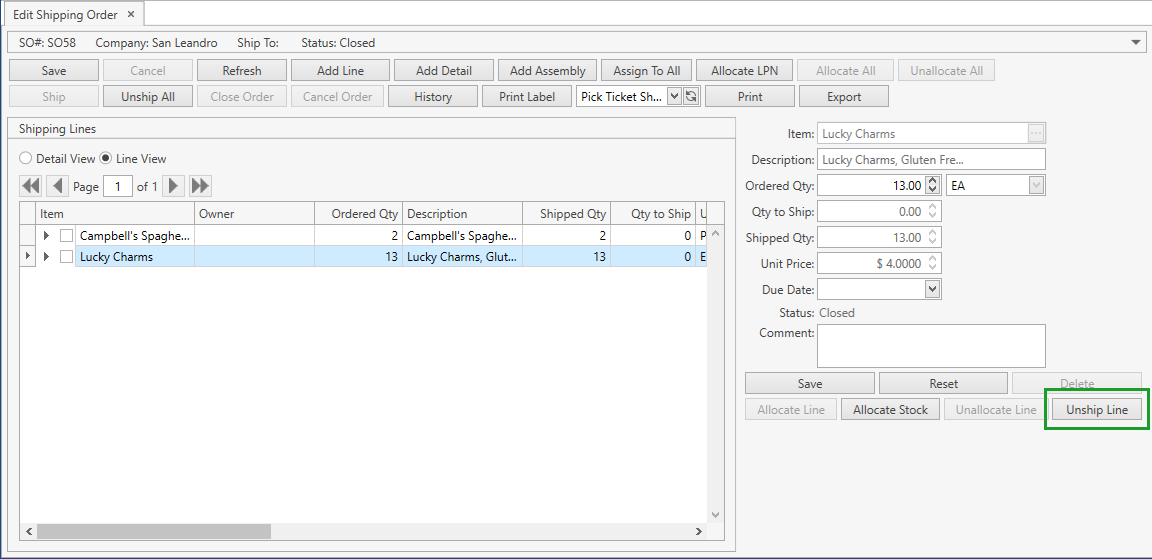

To unship the whole order:

- Click Unship All button:

You will get the following result:

- Shipping Order gets New status.

- Lines get New status.

- Shipped Qty of all lines is equal to ‘0’.

- All details are deleted.

Notes:

- Unshipped Qty cannot be bigger than Shipped Qty.

- Reallocate unship mode can be applied only during Unship Stock operation – you cannot reallocate stock after Unship All or Unship Line operations.

- Reallocate unship mode is not allowed if after Unship operation CoreIMS creates a stock(s) with negative quantity.

- If you unship a detail(s)/line(s) of a service item, the detail(s) will get New status and Shipped Qty for the respective line(s) will be updated accordingly.

- Once you unship stocks of non-service items and/or details of service items, the respective shipping records are deleted from Shipping Documents (Bills of Lading).

Cross-Docking

Cross-docking is a feature that supports the automatic shipping of newly received stocks against a Shipping Order without the prior allocation of these stocks.

Please refer to Receiving: Cross-Docking section for more details.

History

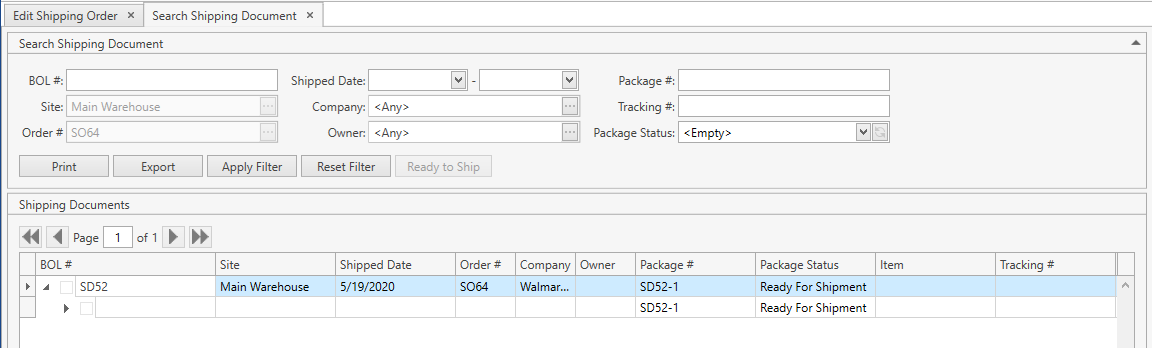

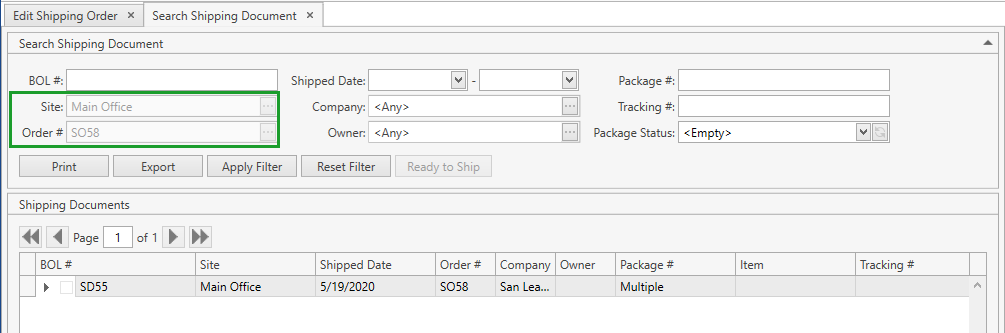

You can view all Shipping Document (BOLs, i.e. Bills of Lading) generated for a Shipping Order by clicking History button. The following window will show up:

CoreIMS prepopulates Site and Order # fields and makes them disabled as you're accessing Search Shipping Document window through the specific Shipping Order. This means that you will be able to see Shipping Documents only of this order.

Please refer to Search Shipping Document section to view the operations you can perform from Search Shipping Document screen.

Print Labels

You can print a label for the order line(s)/detail by clicking Print Label button. This is a common CoreIMS functionality. Please refer to this section for details.

Shipping Order Reports

You can print or export the reports for the specific Shipping Order. These reports are available from the drop-down list highlighted in the screenshot below:

Select one of the following reports and click Print or Export button:

Packing List Shipping Order: Report displays all shipped details that have to be packed for shipping.

Pick Ticket Shipping Order: Report displays a list of allocated stocks that have to be picked up and brought to the shipping zone for shipping.

Shipping History: Report displays the data on all shipments within the current Shipping Order with the detailed information of each Shipping Document, i.e. Bill of Lading.

Shipping Order: Report shows the information on the order header and lines.

BOL #: Report shows the information on selected Shipping Document, i.e. Bill of Lading (BOL). You should select the exact BOL to be printed/exported:

BOL Signable # report is also available for Shipping Orders. Refer to this section to find out how to operate with this report.